Baoji Thread gages Co., Ltd was founded in September 2007 with a registered capital of 5 million and a gross investment of more than 30 million. It is a domestic technical enterprise focusing on the production of various thread gages, oil-specific pipe gauges and petroleum-specific pipe gages and a variety of special button thread gages.

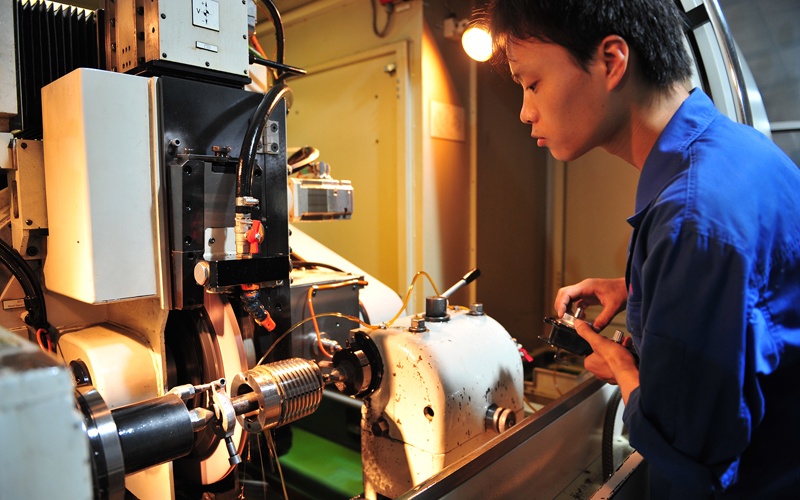

The company is well-equipped with more than 30 sets of brand-new equipment, including general and CNC lathes, milling machines, internal and external cylindrical grinders, surface grinders, vertical shaft rotary table grinders, magnaflux, CNC marking machines, etc. The company imports the world's advanced Matrix internal and external CNC thread grinding machines and German Zeiss three-coordinate thread measuring machines to ensure the processing and measuring accuracy of products from manufacturing to product testing, and the annual production capacity of up to 2500 sets of thread gauges.

At present, the company has more than 50 employees, including 3 senior titles, 3 intermediate titles, more than 30 technical workers, and senior technicians with more than 30 years of experience in designing and manufacturing thread gauges. He has participated in the drafting and review of API SPEC 7-2, API SPEC 5B, GB/T 22512.2-2008 (Petroleum and natural gas industries. Rotary drilling equipment. Part 2: Threading and gauging of rotary shouldered thread connections), and API SPEC 5B 15th Edition 2008-10-01 (Threading, Gauging, and Inspection of Casing, Tubing, and Line Pipe Threads).

Baoji Thread gages Co., Ltd has been authorized by the American Petroleum Institute API (API SPEC 7-2-0680, API SPEC5B-0032) and is a professional company specializing in the production and sales of petroleum thread gage products in China. We have a perfect quality assurance system and a strict scientific management system.

Our products are used in CNOOC, Sinopec Shengli Oilfield, PetroChina Huabei Oilfield Company, Shandong Molong Petroleum Machinery Co.Ltd, China National Petroleum Baoji Petroleum Steel Pipe Co. Calibration, China National Petroleum Baoji Petroleum Steel Pipe Co., Ltd. and other major oilfields and oil-specific pipe manufacturers in China. The products also supply Weatherford oil Tools. Middle East LTD, Third Coast Gage & Calibration, Sonsan Sondaj Sanayii LIT.STI., Energogazpostavka., Co.Ltd., MTQ Oilfield Services WLL, Premium Co., Ltd, etc. are located in Asia, Africa, Latin America, Europe, America, Oceania, and other countries and regions.

Baoji Thread gages Co.,Ltd. will always adhere to the enterprise management strategy of "Take quality as a premise of competition, Take the market as the operation orientation, and strive to create international and domestic markets", constantly pursue the improvement of product quality, steadily improve brand awareness, and gradually make "SRT" into a brand trademark of thread gauges in the petroleum equipment products industry.

TEL

TEL